4/9/19 A customer from the Czech Republic operates a data centre and uses Unipi Axon controllers to measure differential pressure of the cooling air.

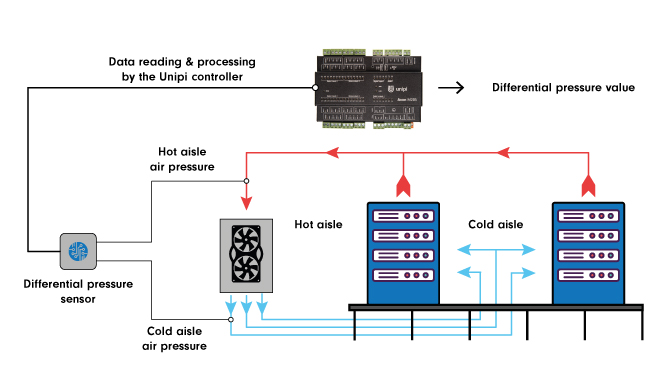

A hot/cold aisle cooling method is often considered a standard for cooling in datacentres. In this arrangement, server racks are placed in rows facing each other and the cold cooling air is fed by a CRAC (Computer Room Air Conditioning) unit through an enclosed corridor within the elevated perforated floor (aka "cold aisle"). The hot air ejected by the servers is then flowing upwards and propelled by ventilation back into the CRAC unit (aka "hot aisle"). The CRAC unit then cools the hot air and propels it back to the cold aisle, repeating the process.

In the ideal case, the cold aisle pressure should be higher to ensure proper airflow. However, if the datacentre is expanded by additional server racks both cold and hot aisles have to be extended. Sooner or later, a need will arise to determine whether or not the CRAC unit possess a sufficient power output to maintain the airflow. The easiest method to solve this question is through measurements of the differential pressure, representing a difference of pressures in cold and hot aisles.

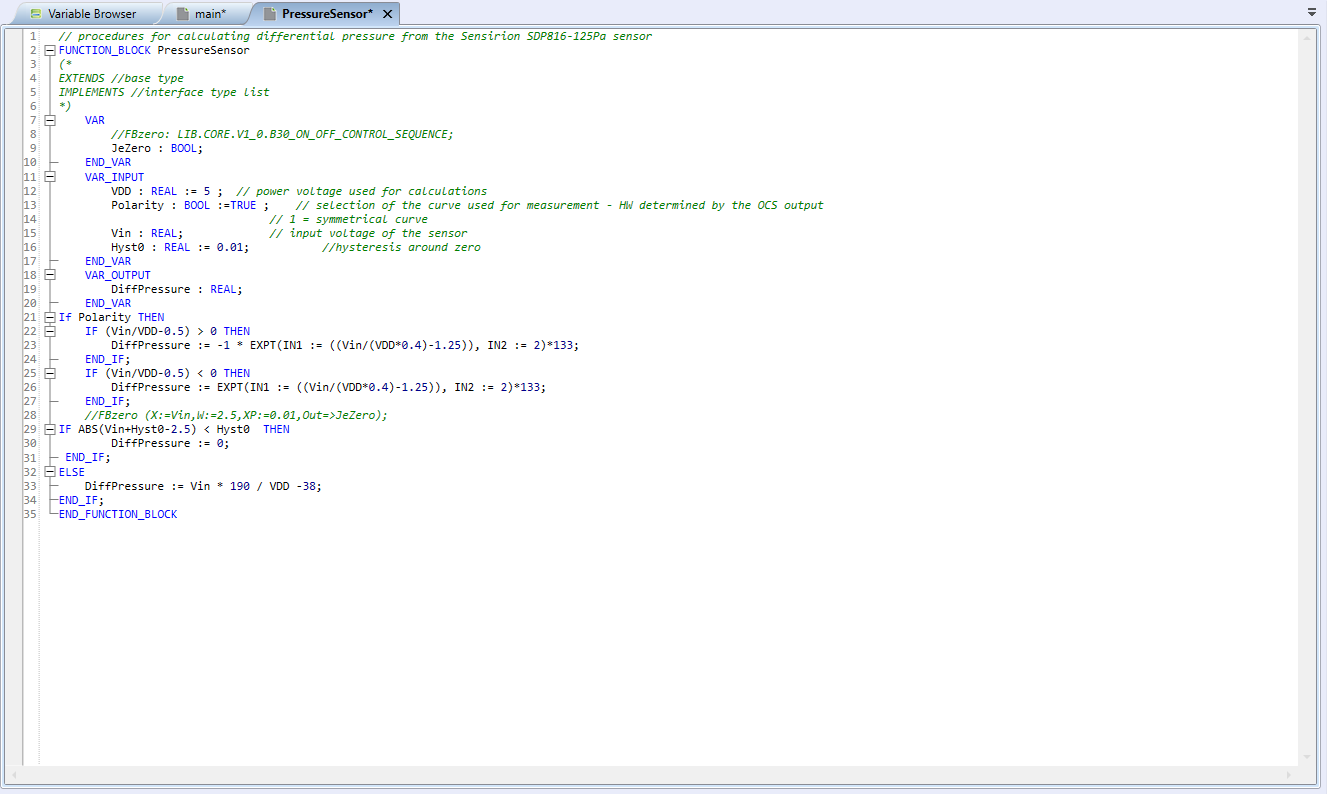

A customer with the exact same need approached the Unipi technology team, requiring a project combining differential pressure sensor with the Unipi Axon M505 programmable logic controller; this model features three RS485 serial interfaces, additional analogue I/O's (5× AI/5× AO) and the usual set of digital I/Os and relay outputs. The sensor's input voltage is transferred to the controller's analogue inputs, and after measurements and filtration, the values are then stored to a cloud database. From the software point of view, the project utilizes the Mervis software platform - the officially supported control software developed under the IEC 61131-3 standard for PLC programming. The sensor's function block, created by the Structured Text (ST) method, performs calculations of differential pressure based on an input voltage of the sensor.

Code of the sensor's function block including a description of individual variables

Code of the sensor's function block including a description of individual variables

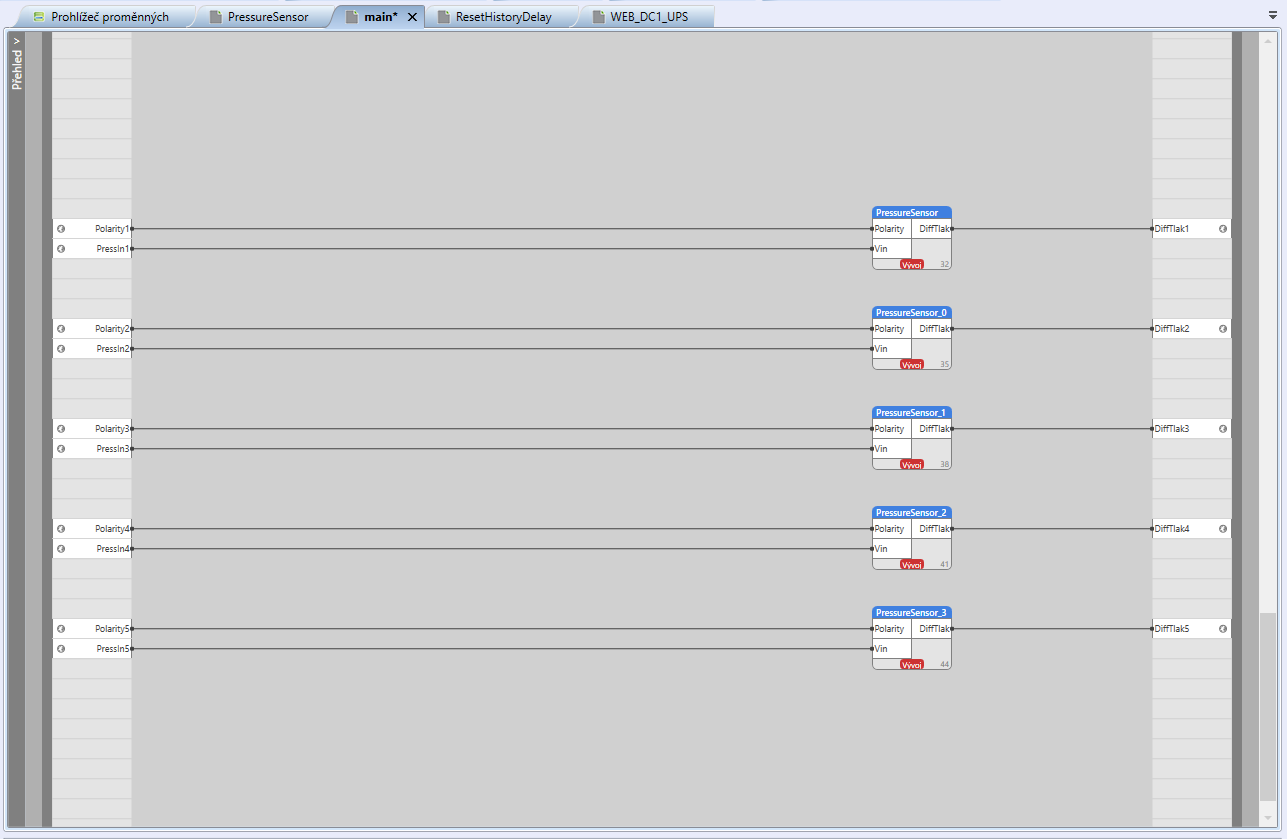

Connection of several differential pressure sensor function blocks in the Mervis IDE

Connection of several differential pressure sensor function blocks in the Mervis IDE

The function block has two inputs - a Polarity input determining the curve used for the measurement, and a PressIn input representing a measured input voltage of the sensor. The block's output then represents the calculated differential pressure expressed by a real value. This value is then stored to a Mervis DB cloud database for further analysis and processing.

The customer plans to place a total of six sensors around the data centre. However, both the sensor and its program can be effectively put to use in other applications requiring differential pressure measurements. A typical example of such application are large air conditioning units in which differential pressure value can be used to monitor the status of air filters, using the difference between input and output pressure to determine whether or not the filter is clogged and requires maintenance or replacement.

A sample Mervis IDE project containing the sensor's function block can be downloaded on this link.

Note: The function block can be used only with Sensirion SDP816-125Pa differential pressure sensor. To use it with a different type of sensor the block's formula must be adjusted according to the sensor's parameters.