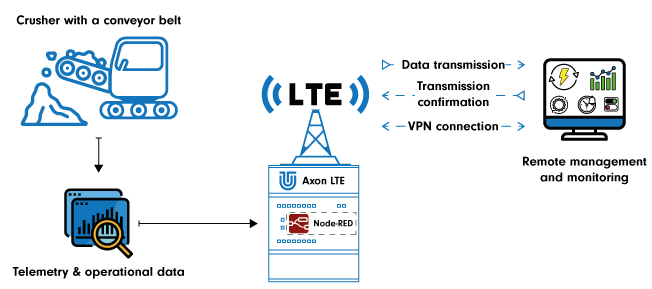

The VETRA International company uses Axon LTE controller for monitoring of a belt conveyor and transmitting of the data via the wireless LTE network.

VETRA International s.r.o. is a Czech company founded in 1991 that provides its customers with distribution, installation, service and maintenance of mobile weighing systems. As a development of one of its standard products, the company deployed Unipi Axon LTE controllers for monitoring and remote management of a conveyor belt mounted on a mobile impact crusher.

The crusher is usually deployed in remote or hard-to-access locations. That necessitated the use of wireless technology to ensure reliable data transmission. Given the fact such locations also suffer from issues with signal strength, the data is transmitted only after the server confirmation to maintain data integrity. This requirement means the gateway, outside of featuring wireless communication, must be also able to run a complex logic. Finally, as the hardware is placed in a durable metal box to protect it against the harsh environment. The project also required an external antenna able to function even with low signal strength.

Simplified schematic of the project

In the end, the company opted for the Unipi Axon M265 LTE programmable logic controller; it is one of the latest Unipi Axon models that not only features a variety of communication interfaces (RS485, 1-Wire) and a set of digital, relay and analogue I/Os, but is also equipped with an LTE interface, allowing it to use the high-speed LTE wireless network for communication. An external antenna is included in the package and the controller itself, as all Axons, is based on the open-source Linux OS. Both features played a major role in the company's decision to purchase the controller.

The installation consists of the Axon controller placed in a durable metal box mounted on the crusher itself. The controller collects weighing data, data about processed material and telemetry of the crusher's conveyor belt. This data is then transmitted via the LTE network to an online user interface, using encrypted MQTT protocol. In this interface, the user can monitor the crusher's status and its operational data. The LTE network is also used for sending messages confirming a successful data transmission and for establishing a secure VPN access for remote maintenance and diagnostics. The entire control logic is created in the Node-RED software platform.

Next step

Photo documentation

Crusher with a conveyor belt monitored by the Axon LTE controller

Crusher with a conveyor belt monitored by the Axon LTE controller