Use of automation products in industry to improve manufacturing efficiency.

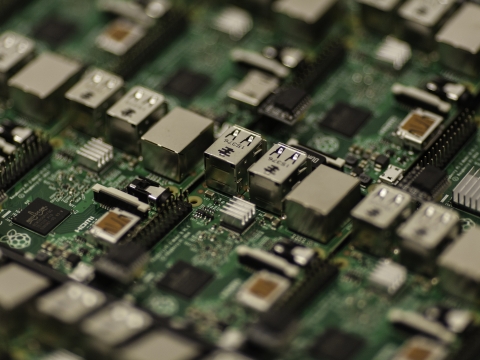

Van Genechten Packaging is a carton board packaging company from Belgium. Since 2013, the company's IT department is implementing Raspberry Pi single-board computers into the production environment. At first, the company used a custom-developed I/O module, but later, a decision was made to combine it with our UniPi 1.1 control unit. The resulting project was named Smart Factory Unit (SFU).

Specific Uses

The system has the following parts, each of them having its specific purpose:

- SFU energy: serves for power consumption measurement in the company's data centres and the factory

- SFU thin client: thin client allows access to the company ERP system directly from the production facility

- SFU meter: monitoring of the environment (temperature and humidity) of data centres

- SFU music: control of the music played at the reception via an online user interface

- SFU counter: reading data from counters on factory machinery

- SFU loading dock: automatic control of the palette processing and shipping process.

Most important parts of the whole process are SFU counter and SFU loading dock. The former collects readings from sensors and machine production speed calculations (~150 000 pi/h). SFU loading dock is an application used for automation of the product loading process. The application monitors the loading of palettes into a transporter at the loading gate and also indicates shipment in the cargo bay. The loading dock is also provided with light and sound signalization.

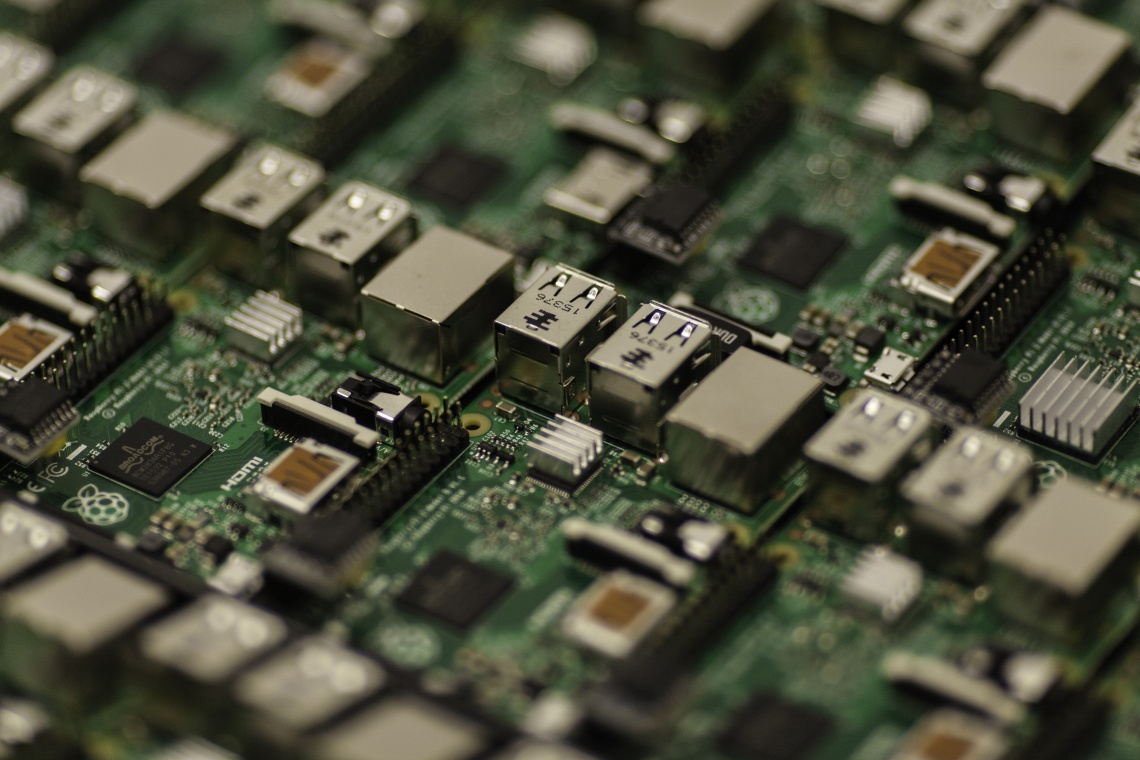

The company's IT department is also working on "Work in Progress tracking" application. Each palette inside the factory is tagged with an RFID tag and the system then tracks it on its way through the factory with RFID readers. These are connected by an RS485/422/232 - USB interface to the UniPi control unit. The application also contains sensors for detection of palette height, connected via analogue inputs. UniPi itself is attached to a DIN rail placed in a control box along with other modules. All data readings (timestamps, pallet height measurements, RFID tag ID codes etc.) are uploaded into the ERP (Enterprise Resource Planning) system.

.jpg)

The detail of a control box

Prepared control boxes

Used serial RS485/RS422 - USB adapter